Customization Of Motors, Gear Box, Heat Exchanger etc.

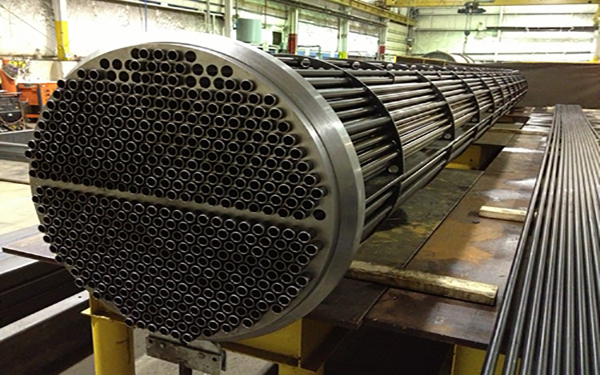

Depending on the overall function and location, heat exchangers come in a variety of configurations. Generally, they are built with a flat plate design or a shell and tube design. Air, liquids, or steam flow through a network of heat conducting tubes or cavities lined with heat conducting plates.

Plate heat exchangers come in two basic configurations—flat plate heat exchangers or plate and frame heat exchangers. Air to air and water to air heat exchangers are made with this configuration. Shell and tube heat exchangers are available in configurations such as finned tube heat exchangers, tube heat exchangers, spiral heat exchangers, or oil coolers. Marine and other water-to-water heat exchangers usually are equipped with this design.

There are several types of gears viz external gear with the teeth formed on the outer surface of a cylinder or cone and internal gear with the teeth on inner surface. Gears are generally specified by their type of tooth and blank shape e.g. spur, bevel, spiral etc., material, size or dimensions, geometry and special features, if any. The main types of gears can be classified as Spur, Helical, Worm Gears, and Bevel Gears etc.

Gears are widely used in various mechanisms and devices to transmit power and motion positively without slip between parallel, intersecting axis and non-intersecting, non-parallel shafts, without change in the direction of rotation, with change in the direction of rotation, without change of speed of rotation, with change in speed at any desired ratio.

Heat Exchanger

Heat Exchanger